Globalization; the good, the bad and the ugly! It has afforded us access to a broader supply base which is good but it can very quickly turn bad and ugly. We often like to ask our clients, “Would your organization be prepared if”:

- A major European port is shut down for weeks due to a strike, earthquake, hurricane or attack?

- A major tier two offshore supplier suddenly moves their operations onshore?

- The lead time – not to mention the costs – to obtain key commodity inputs triples?

- Sources of energy start shifting significantly (Paris agreement)?

- Instability within Middle East expands and South America goes “red” and continues to nationalize private businesses(GM)?

- War breaks out with North Korea and one of your key suppliers resides in South Korea?

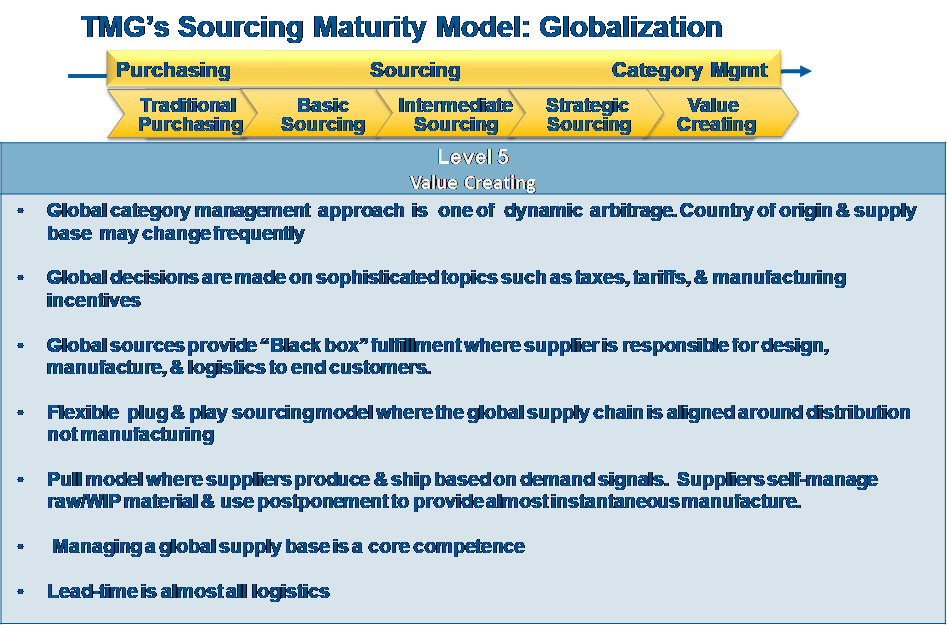

How about if the U.S. imposes $$ billions in tariffs on imported Chinese products? Well, they have, and you better be prepared! Here are some of the attributes of a Procurement organization that is operating at the Value Creating / Category Management level of Maturity:

As a Category Management organization, you must be aware of the issues and challenges associated with globalization and have the sophistication and skillset to be able to adjust quickly. Chinese tariffs are here and many organizations are scrambling to find alternative sources of supply. But, was this a surprise or something these companies chose to ignore? There are many challenges to operating in a globally networked economy. Some are clear and others are not. Here are some of those challenges:

- Strategy – A clear strategy is needed on how to approach the market, structure the deals and an overall plan to make it happen.

- Organizational Alignment – Making sure the organization is aligned with the desired outcome of globalization.

- Economic Conditions – Have contingency plans in place to address economic, social and political conditions and events in a foreign country that might adversely affect supply chain operations – Can you say Chinese tariffs?

- Capturing Value – Managing the proper balance between the need to reduce cost and become more efficient.

- The Cost – What it will cost to enter a new market, outsource or buy offshore – is this a divestiture, joint venture, new provider/recipient relationship, etc.

- Managing Relationships – Making sure that supply chain partners understand what is expected of them in managing the relationship.

A recent article in Supply Chain News, “US China Tariffs: Consider Changing your Supply Chain” provides some practical advice on what to do to minimize the negative effects of the tariffs. I would argue that as soon as this was a possibility, options should have been discussed. Events such as this provide a major opportunity for “us” to take on a leadership role in our companies – from a tactical to a strategic advisor role:

- Flexibility and agility will become critical in your strategies and contracting

- Existing trade agreements may give way to new ones which will significantly shift cost arbitrage

- New regulations and tariffs impact on lead times

- On-shoring and near-shoring competitive again and your ability to identify opportunities to create competitive advantage

- Help stakeholders deal with uncertainty and freeze-up

Today it’s China tariffs and tomorrow it’s a different issue. If your organization wants to make the transition from Strategic Sourcing to Category Management you must “Be ready for ANYTHING”. That will gain you credibility within your organization and get you and your leader a seat at the table in the “C” suite.

Let us know what you think and join in the conversation . . . . .