Let me lay out a hypothetical scenario away from COVID to let us all think at a meta level about this Response Lead Time (RLT) thing. Let’s say you are the head of FEMA and have suddenly been made aware of the following: The National Electric Grid is at severe risk when a widespread disruption will occur involving any physical damage to the transmission capability – the highways of electricity if you will. Here are some things for you to consider.

Multiple competitors: There are multiple competitors involved depending on the geographical spread of the event. That means that getting a coordinated response is a major challenge.

Key component (Large Transformers) is not a warehouse item: One of the key components in the National Grid are the transmission transformers. Some of these are very large, are a huge capital expense (millions for each), have complex storage requirements and have a limited shelf life – not an easy warehoused item 😊. This has a huge impact on total cost.

Long lead time: Some of these transformers have a 18 – 24 month lead time and suppliers can’t hold a buffer stock either. At the time of a wide-spread event where multiple utilities need them at the same time, the supply market cannot deliver.

Different standards and specifications: Each utility (competitors) thinks they have the perfect design and specifications for their transformers and therefore these are not plug and play. More variability means more design and manufacturing cost, longer lead times, significantly higher shipping and warehousing costs etc. etc. etc.!!!

Shipping is highly complicated: Special vessels/containers require select roads and rail lines with coordinated road closures, etc. to move them. Therefore, proximity of manufacturing location is a key challenge. You cannot call up Budget and rent a truck😊. This has a huge impact on total cost.

Supply market has limited surge capacity: The supply market cannot surge their capacity in times of stress to meet demand. Both the primary and secondary supply base does not have that kind of capacity.

Global implications: A fair amount of capacity is NOT domestic and therefore subject to global risks which are of significant concern.

Regulators: This is a highly regulated industry with significant requirements when it comes to things like Large Transformers. They are also concerned about information sharing between competitors.

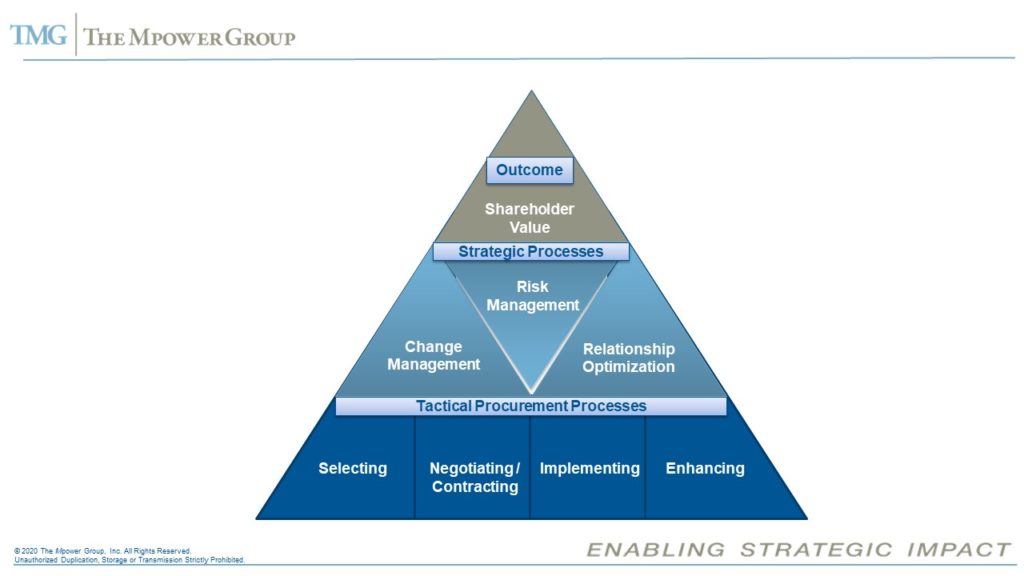

Let me stop here and first talk about how this is related to COVID. The scenario I’m laying out is reasonable and plausible – in fact, it’s Predictable and Inevitable? And I don’t believe any of the assumptions are too far-fetched? The question for you as the head of FEMA is how would you deal with this? What would be your solution? How would you go about it? What challenges do you see? What types of processes and competencies will be critical in dealing with this? We’ll give you a week or so to think about this scenario and formulate your thoughts. In the meantime, let me be transparent with you and let you know that this is NOT a hypothetical scenario but something that the federal government is actually worried about and working on. In fact, we were fortunate enough to be asked to help and this is therefore an actual case study of one of our recent client engagements, so stay tuned to this channel and we’ll share the details of the engagement including which processes were critical (hint:Strategic).

The point of this discussion is that this RLT is a real thing and can be worked on as a real thing and you can build permanent organizational capability around it as a real thing. It is absolutely a competitive advantage and you should be laser focused on it.